desin optimum performance bowl mill

Innovative Combustion Technologies, Inc.

ACHIEVING OPTIMUM PULVERIZER PERFORMANCE AND FUEL LINE BALANCE . 2367 Lakeside Dr. Ste. A-1 Birmingham, AL 35244 (205) 453-0236 ... Proper Roll to Bowl Clearance

获取价格

Design and Modify of Mill Discharge Valve Using in

Mill should be operated at the design air flow atall loads. operating at higher air flow will causes excesswear and upset the performance of classifier etc. if mill isoperated at lower air

获取价格

Pulverizers 101: Part I - POWER Magazine

2011/8/1 The design "capacity" of that same pulverizer is 135,000 pounds per hour with fuel that is 55 HGI, 3/4-inch raw coal maximum size, and 7%

获取价格

Bowl Mill Coal Pulverizer - COAL HANDLING PLANTS

2023/12/14 Components of Bowl Mill Coal Pulverizer Gearbox. It is driven by an electric motor, is directly connected to the bowl hub. A planetary gear arrangement provides the proper reduction between the motor and the bowl

获取价格

THERMAL POWER PLANTS: BOWL MILLS

2010/8/29 **Optimum design. Ensure optimum arrangement of the mill throat and the coal flow path to improve mill performance. * *Close tolerances. Pulverized coal mills with throats that are too wide will have corresponding low

获取价格

Desin Of Optimum Performance Bowl Mill - dziendobry

Bowl Mill Study 1 PDF Mechanical Engineering Nature Scribd. Inspection When inspecting the pulverizers, the following items have been found to be critical in achieving optimum pulverizer

获取价格

desin of optimum performance bowl mill

Optimising mill circuits for best efficiency impact. By Guest Contributor. Oct 26, 2021. Wireless LoadIQ system installed on the mill shell from which it gather mill mechanical and operational

获取价格

Pulverizers 101: Part I - POWER Magazine

2011/8/1 The design "capacity" of that same pulverizer is 135,000 pounds per hour with fuel that is 55 HGI, 3/4-inch raw coal maximum size, and 7% moisture. ... A bowl mill spring or hydraulic preload for ...

获取价格

“Blueprint” Your Pulverizer for Improved Performance

performance is governed by uniform coal combustion by the burn-ers and satisfactory coal fineness. Adequate fineness for both west-7. Optimum design. Ensure optimum arrangement

获取价格

Ray Bowl Mill PDF Mechanical Engineering Industries

The document provides guidelines for inspecting key components of a Raymond bowl mill, including roll-to-bowl clearances, pulverizer throat area, general condition, classifier blade synchronization, deflector ring, and inverted cone

获取价格

What to Look for in Hammermill Design for Optimum

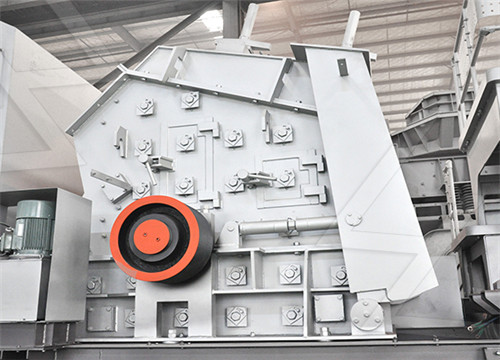

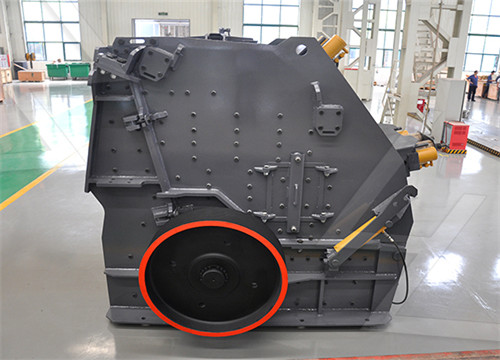

2022/5/12 Mega Mill Hammermill Design. Prater’s Mega Hammermill helps bridge the gap between the company’s G-series hammermills and its fine grinders. Benefits of Prater’s Mega Mill Hammermill design include:

获取价格

design of hammer mills optimum performance – Grinding Mill

Gulin Least News. Optimizing manganese ore sinter plants: process parameters and design implications » The More » crushed stone cost per yard » small maize grinding mill for sale in

获取价格

Bowl Mill (Pulverizer) in Thermal Power Plant

2024/11/20 The mill should operate at its design airflow to prevent wear and ensure proper coal fineness. Deviations can result in coal rejects or excessive fineness, both of which reduce

获取价格

A case study of how vertical spindle pulverizer performance

a STI design used for optimum vectoring, improved classification and reduced mill rumbling is seen as figure 3. Figure 3: STI Deflector Rotating Throat B. Regardless of whether the

获取价格

E-BOOK Three factors that determine the wear life and

life and performance of mill liners and how to keep your mill running at optimal performance. A horizontal mill is the most common type and consists of a cylindrical shell, which is driven by a

获取价格

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes

获取价格

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Performance ...

2023/3/15 BHEL for evaluation of Coal Bowl Mill, for guaranteed performance at a 500 MW capacity NTPC thermal power plant. The study was conducted to assess the effective

获取价格

A case study of how vertical spindle pulverizer performance

a STI design used for optimum vectoring, improved classification and reduced mill rumbling is seen as figure 3. Figure 3: STI Deflector Rotating Throat B. Regardless of whether the

获取价格

E-BOOK Three factors that determine the wear life and

life and performance of mill liners and how to keep your mill running at optimal performance. A horizontal mill is the most common type and consists of a cylindrical shell, which is driven by a

获取价格

Coal mill pulverizer in thermal power plants PPT

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50,

获取价格

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Performance ...

2023/3/15 BHEL for evaluation of Coal Bowl Mill, for guaranteed performance at a 500 MW capacity NTPC thermal power plant. The study was conducted to assess the effective

获取价格

git.sr.ht

``` sbm desin of optimum performance bowl milldesin of optimum performance bowl mill desin of optimum performance bowl mill.Planta Móvil de Trituradora de Mandíbula.Planta Móvi

获取价格

Raymond Bowl Mill Inspection Guidelines -

2013/4/21 Attention! Your ePaper is waiting for publication! By publishing your document, the content will be optimally indexed by Google via AI and sorted into the right category for over 500 million ePaper readers on YUMPU.

获取价格

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

pulverizer 1003 XRP Bowl Mills shown at Figure 1, for guaranteed performance at a 500 MW capacity NTPC thermal power plant. The cross section of the coal bowl mill is shown in Figure

获取价格

"Blueprint" Your Pulverizer for Improved

2009/3/1 Step 1. Ensure that the grinding elements are in good condition. Make sure that the grinding surface profiles are optimum. That means using the original design grinding profiles for your mill.

获取价格

MILL performance.ppt - SlideShare

2023/8/7 This phenomenon is more predominant in bowl mills. If the mill is loaded beyond its capacity w.r.t. its wear life, the performance will suffer. ... mill DP indicates the amount of coal inside the mill. If the DP is allowed to cross

获取价格

Design of hammer mills for optimum performance

2013/10/1 Download Citation Design of hammer mills for optimum performance In hammer mills, the grinding process consists of hitting the material by hammers, articulated on

获取价格

Design of hammer mills for optimum performance

2012/8/28 In hammer mills, the grinding process consists of hitting the material by hammers, articulated on a rotor. It is important, however, that the percussions applie...

获取价格

Innovative Combustion Technologies, Inc.

ACHIEVING OPTIMUM PULVERIZER PERFORMANCE AND FUEL LINE BALANCE . 2367 Lakeside Dr. Ste. A-1 Birmingham, AL 35244 (205) 453-0236 ... temperatures within design

获取价格

Quality Experience Matters - Mantles Bowl Liners - Optimum

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life

获取价格

“Blueprint” Your Pulverizer for Improved Performance

performance is governed by uniform coal combustion by the burn-ers and satisfactory coal fineness. Adequate fineness for both west-7. Optimum design. Ensure optimum arrangement

获取价格- Дунг Мэн горячая конусная дробилка

- Высокая Эффективность Нового Каменного Дробильного Завода

- позвонил сокрушительное г

- производители суппортом стол

- принцип работы и описание шаровых мельниц

- Дробилка Run Glens Falls

- стеклянные фрезерные станки для продажи Южная Африка

- оборудование операция карьера espana

- ленточный конвейер фотографии высокого

- поставщик шаровой мельницы в чандигаре

- Определение флотационных шин

- в наличии мобильные дробильные ус

- б конусная дробилка для речного камня для продажи

- Отдельный золотой депозит через электромагнитный

- как мне найти дробилки золотую из германии

- дробилка щековая качели вала цена

- Образование ленточного железа в Южной Кассинга Ангола

- проектирование и расчет вибрационных грохотов

- грохот эксцентриковый купить цена стоимость

- технология изготовление гипсового блока обработка материалов

- щековая дробилка 1930 х годов

- Как настроить план переработки железной руды

- как продать пластмассовую мельницу

- пименение искуственного песка

- камнедробильная машина среднего размера